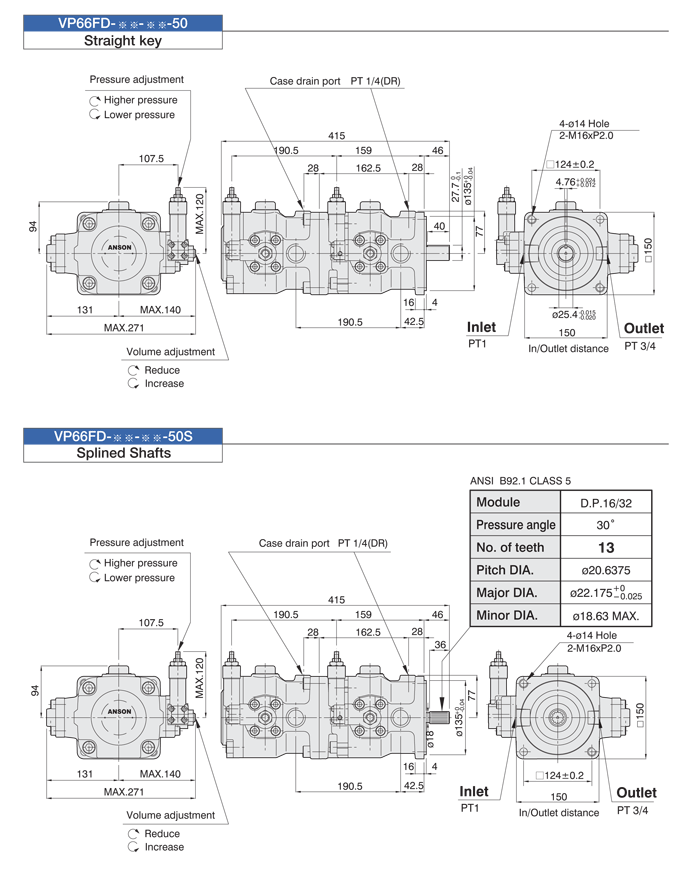

VP66FD Series variable double vane Pumps

How to order:

Variable Displacement Vane Pumps

VP※※FD Series-Double Pumps Model Code

| VP55FD |

-A |

-5 |

-A |

-5 |

-50 |

S |

|

Code

Frame size

|

Shaft end pump |

Cover end pump |

Design |

Shafts code |

Outlet flow

(at 3.5bar,1800 r/min) |

Operating pressure range |

Outlet flow

(at 3.5bar,1800 r/min) |

Operating pressure range |

A

Outlet Flow L/min

(Geometric displacement cm3/rev) |

●B

Outlet Flow L/min

(Geometric displacement cm3/rev) |

Code |

Pressure range

(bar) |

A

Outlet Flow L/min

(Geometric displacement cm3/rev) |

●B

Outlet Flow L/min

(Geometric displacement cm3/rev) |

Code |

Pressure range

(bar) |

VP55FD

(VP5FD) |

30 (16) |

40 (22) |

2 |

15~35 |

30(16) |

40(22) |

2 |

15~35 |

50 |

Omit:

Woodruff key (VP5*)

Straight key (VP6*)

S:

Splined Shaft |

| VP65FD |

54 (30) |

70 (39) |

3 |

20~70 |

30(16) |

40(22) |

3 |

20~70 |

| VP66FD |

54 (30) |

70 (39) |

4 |

50~105 |

54(30) |

70(39) |

4 |

50~105 |

F:

Flange mounting |

●B code (40 & 70 L/min)

maximum pressure 105bar

Factory setting Q max. |

5 |

70~140 |

●B code (40 & 70 L/min)

maximum pressure 105bar

Factory setting Q max. |

5 |

70~140 |

| Factory setting Pmin. |

Factory setting Pmin. |

※Pumps Speed Limits

Minimum speed:800 r/min

Maximum speed:1800 r/min

Combined variable vane pump - hydraulic oil pump - vane pump - jinzhong oil pump - variable pump

1. Special pressure-limited variable mechanism can realize large flow rate of low voltage and small flow rate of high voltage, so that the most reasonable use of power can effectively reduce motor power consumption and save energy.

2. The double-variable pump is connected by two single-variable vane pumps to achieve the effect of space saving.

3, the temperature rise is small, if the company's air-cooled cooler, more can achieve the temperature rise control effect. Double vane pump is composed of two single-stage vane pump installed in a pump body in parallel on the oil circuit.

4, the use of special structure to achieve smooth operation, with low shock and low noise characteristics, very suitable for machine tools, shoes and machinery with high noise requirements.

5, can be connected to the direct motor, easy installation.

6. The built-in pressure regulating valve is unnecessary for the system.

7. It can supply pressure and flow of different circuits at the same time. When fast feed, the two pumps supply oil at the same time (at this time the pressure is low), when the work feed, by the small flow pump supply oil (at this time the pressure is high), at the same time on the oil system to make the large flow pump unloading, which compared with the use of a high pressure large flow pump, can save energy, reduce oil fever.

8. High efficiency variable pump is a special pressure control mechanism and forced parallel mechanism with automatic regulation of flow and compensation function, to save energy. This double vane pump is also often used in the hydraulic system of machine tools need two independent oil circuit. Double vane pump is often used for the rapid feed and work feed requirements of the mechanical processing of the special machine tool, when the double pump by a small flow and a large flow pump composition.

. The rotors of the two vane pumps are driven by a unified drive shaft and have separate oil outlets. The two pumps may have equal or unequal flow rates.

Pump displacement and flow

(1) displacement V. Hydraulic pump shaft every turn, by its sealing volume geometric size changes calculated by the volume of oil, known as the displacement of the pump. Also known as the theoretical displacement or geometric displacement. The common unit of displacement V is. Mm 3 /r, the size is only related to the geometric size of the pump.

(2) theoretical flow, Hydraulic pump in unit time theoretical discharge of oil volume. If the speed of the pump is,,, the theoretical flow rate of the pump is cp=Vn,, and the common units of are m 3 /, or L/min.

(3) rated flow rate. Hydraulic pump in rated speed and rated pressure when the actual output flow. Pump nameplate or product samples marked flow rate for the pump rated flow.

(4) actual flow q. Hydraulic pump in the unit time of the actual output of oil volume. Because the hydraulic pump in the work there is leakage flow Oq. So the actual flow q is less than the theoretical flow qt

Q =, a delta q (13-1)

It needs to be pointed out that when the pump outlet pressure is zero or the difference between the inlet and outlet pressure is zero, the pump leakage Aq=O, namely q=q, O. Therefore, in the industry, the pump flow under zero pressure is often regarded as the theoretical flow.

14 years of experience design manufacturers tell you, as long as the quality is good what does not matter, the price is expensive is actually cheap, because the company of a pump when other manufacturers of 10 pumps to use, as if you buy a pump of my company can use for 10 years, and other manufacturers do not know about a few months on the bad. Then you have to spend money to buy a pump. Value customers know best.