VP6F Series variable single vane Pumps

How to order:

Variable Displacement Vane Pumps

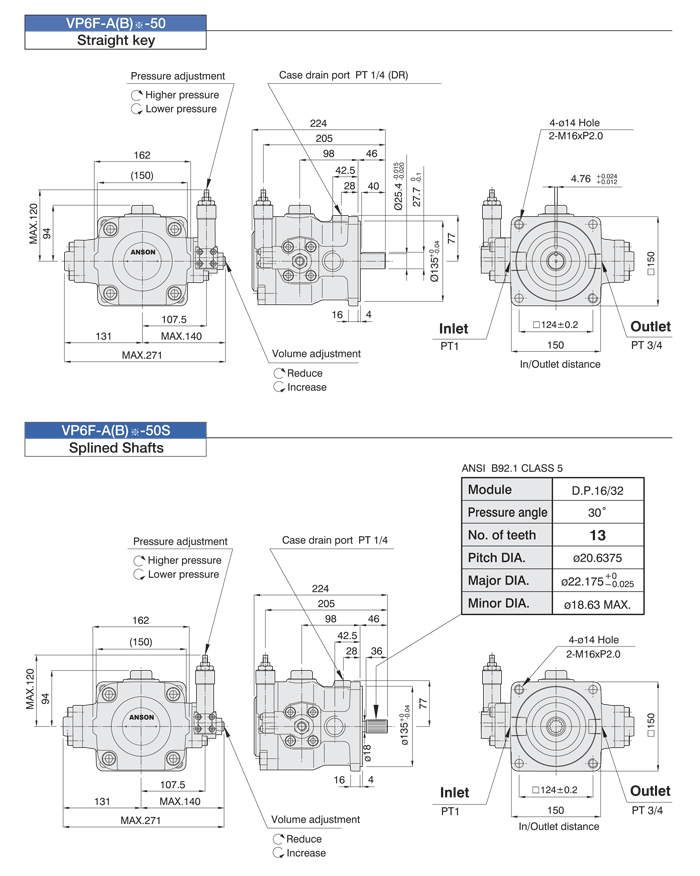

VP※F Series-Single Pumps Model Code

| VP5F |

-A |

-5 |

-50 |

S |

|

Code

Frame size

|

Outlet flow

(at 3.5bar,1800 r/min) |

Operating pressure range |

Design |

Shafts code |

A

Outlet Flow L/min

(Geometric displacement cm3/rev) |

●B

Outlet Flow L/min

(Geometric displacement cm3/rev) |

Code |

Pressure range

(bar) |

| VP5 |

30 (16) |

40 (22) |

2 |

15~35 |

50 |

Omit:

Woodruff key (VP5)

Straight key (VP6~7)

S:

Splined Shaft |

| VP6 |

54 (30) |

70 (39) |

3 |

20~70 |

| VP7 |

120 (67) |

- |

4 |

50~105 |

F:

Flange mounting |

●B code (40 & 70 L/min)

maximum pressure 105bar

Factory setting Q max. |

5 |

70~140 |

| Factory setting P min. |

※Pumps Speed Limits

Minimum speed:800 r/min

Maximum speed:1800 r/min

Variable vane pump working principle

The inner surface of the stator of the variable vane pump is a circle. There is an eccentricity between the rotor and the stator. There is only one oil absorption window and one oil pressure window on the oil distribution plate. When the rotor is driven by the motor and rotates in the direction of the arrow shown in the figure, when the blade passes through the lower half of the stator, under the action of centrifugal force, it extends from the blade groove, and the sealing volume between the two blades increases to achieve oil absorption. When the blade passes through the upper half of the stator, the inner surface of the stator is gradually pressed into the blade groove to reduce the sealing volume and realize oil pressure. Pump rotor every turn, each sealed volume suction, pressure oil once. Change the eccentricity between stator and rotor, can change the pump displacement, so called variable vane pump.

Variable vane pump features

1. In order to enable the vane pump to reliably absorb oil, its speed must be within the range of 500 ~ 1500r/min. Too high speed will cause the pump "empty" phenomenon, pump work is not normal. Oil viscosity to choose appropriate, viscosity is too large, oil resistance increase; Oil is too thin, gap effect, vacuum is not enough, will cause adverse effect on oil absorption.

2. The vane pump is sensitive to the dirt in the oil, and its working reliability is poor. The unclear oil will make the blade stuck.

3. Because the pump blade has installation Angle, so the rotor only allows one-way rotation, should not be used in reverse, otherwise it will make the blade broken.