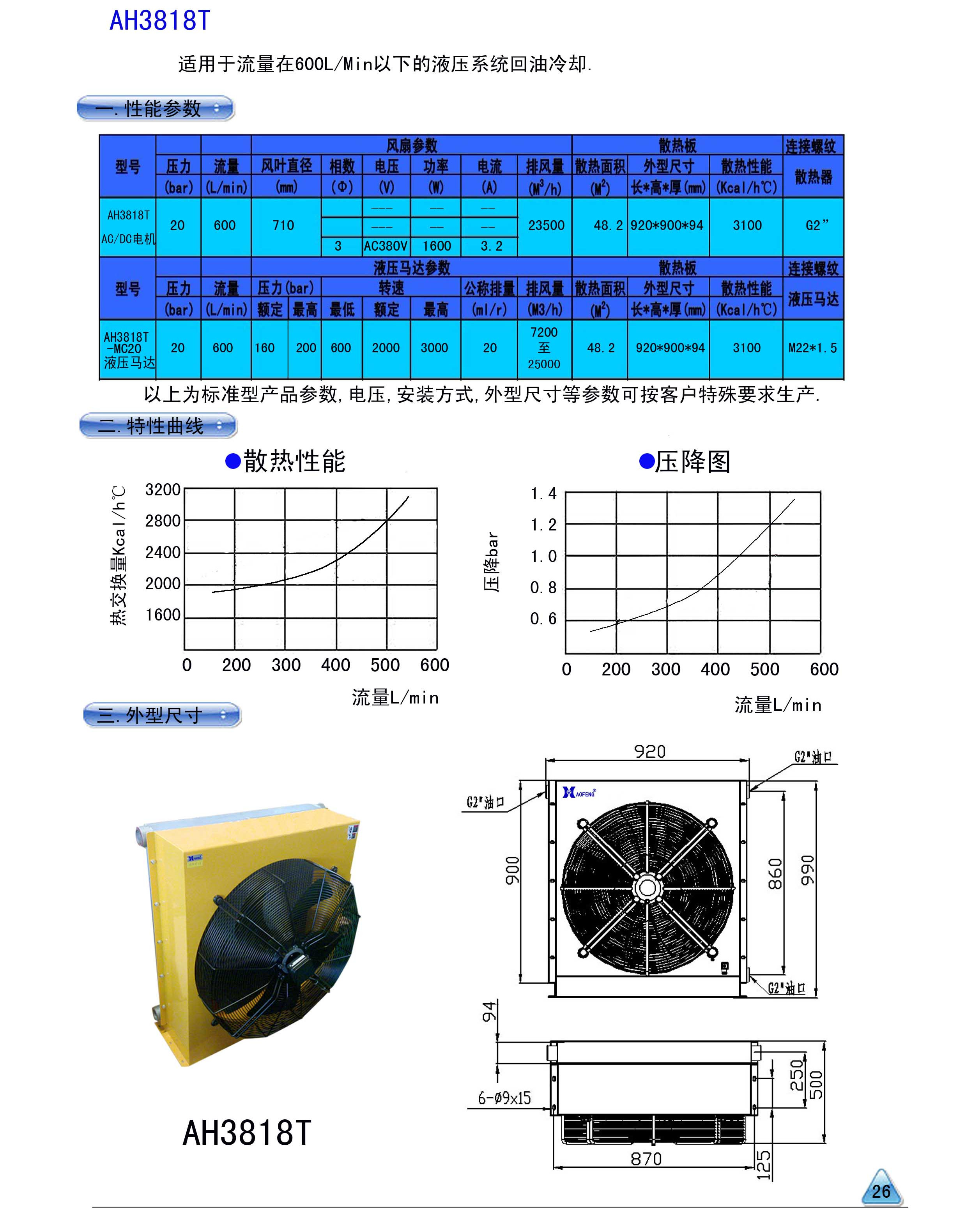

Heat exchanger industrial air cooler AH3818T-AC220V

The cooler material is made of plate-fin aluminum alloy with high strength, which is welded by vacuum with special technology.

Job stress: 20 bar (for high pressure, please call) using temperature is 120 ℃

In order to protect the cooler from cracking, when the cooler is installed in the return oil circuit, when the return oil pressure is greater than 20bar, try to install the bypass drain circuit (one-way valve) and connect it in parallel with the cooler, and confirm that the unloading valve can be opened first in case of shock wave.

Suggested way: use another small pump to extract the hot oil in the oil tank to supply to the cooler, making it into a separate circulating cooler system, and can be installed in this filter device, to ensure the normal operation of the equipment and extend the service life.

Notes:

1. Please install the cooler in a well-ventilated place

2, before the cooler suction and rear tuyere, at least to reserve fan circumference radius size range above, to facilitate air convection.

3. The suction inlet in front of the cooling fan shall be cleaned of dust and sundries regularly.

Precautions for piping:

1. The diameter of the piping should match the mouth of the tooth, and the size cannot be changed.

2. As far as possible, use direct head to bend the steel pipe or use high-pressure hose to reduce oil return resistance.

3, the smaller the bending Angle, the fewer bending times for the principle.

4, as far as possible to use hydraulic oil, reflux faster, smoother, better heat dissipation effect.