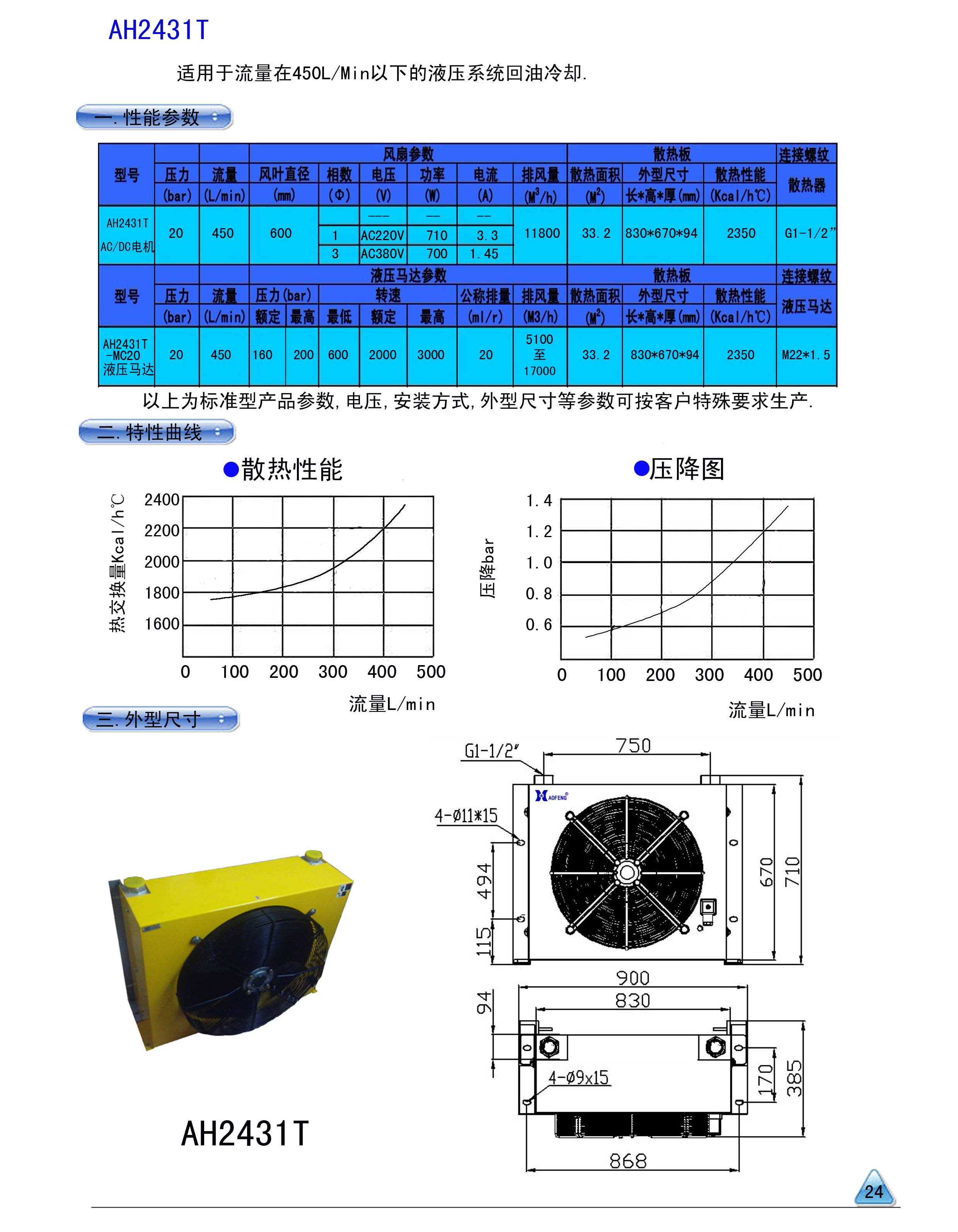

Heat exchanger industrial air cooler AH2431T-AC220V

A. Introduction to the wind cooler

Wind cooler is a kind of cooling radiator, its characteristic is to use air as the cooling medium of heat exchange and heat exchange, heat attached to aluminum alloy fins through contact with air exchange and then by fan suction, so also known as air cooler or air-cooled oil cooler

Ii. Advantages of air cooler

Compared with the traditional water cooling, air cooling does not need circulating water, environmental protection and low carbon, pipeline installation is convenient; Solve to avoid the serious consequence of oil-water mixing caused by the damage of cooler!

Generally used in mechanical engineering cooler water cooling and air cooling, air cooling because of easy installation, easy maintenance, no water source, environmental protection, portability, heat dissipation effect is good, so the air cooler is popular with users green narrow, in the machine machinery, hydraulic system oil cooling; Engineering vehicle hydraulic system cooling, lubricating oil cooling, transformer oil cooling, water glycol cooling, air cooling, natural gas cooling gear tank cooling and other fields widely used!

2. Use and maintenance of air cooler

1. Select the right air cooler specifications according to the actual use

2. The installation position of the cooler should avoid vibration and impact to ensure that the air inlet and exhaust channels are unobstructed and the installation should be firm

3. When connecting the inlet and outlet joints of the cooler, it is necessary to fix the outer Angle clamp of the oil port with a wrench, and tighten the joint, otherwise the heat sink plate may be deformed and damaged, leading to oil leakage

4. The oil inlet and outlet of the cooler are interchangeable. Since the cooler is a low-pressure element, it is necessary to ensure that the core pressure of the radiator does not exceed 0.8mpa

5. When the cooler is applied to the quantitative pump system loop, a 0.5mpa bypass one-way valve should be installed in the inlet pipe because the pulse pressure will be generated when the system operates; The return pipe diameter of the cooler must be 1.5 times larger than the return pipe diameter area

6. The function of the air cooler is to better operate the equipment; The heat dissipation effect of the air cooler depends on the aluminum alloy heat dissipation plate and fan, two core components

7. The finned structure of aluminum alloy heat dissipation plate is easy to gather dust, which will cause wind resistance and affect the heat dissipation effect. At the same time, a large amount of corrosive substances are carried in the dust, which is easy to erode the fin; It is recommended to blow dry compressed air between 0.3 and 0.5MPA from top to bottom for each shift, and pay attention to clean the dust blown to the housing. Otherwise, the next time the fan starts, it will be brought to the fin to cause high temperature. If the environment is bad, the cooler will absorb a lot of oil. It is necessary to use the knot carbon cleaner to clean it

8. If the air cooler is not used for a long time, it needs to be stored in a dry place; Do not need to consider for a long time to add some inert gas in the movement

9. If it is used for walking machinery; Outdoor environment should pay attention to avoid long-term exposure to the sun and rain

10. When the cooler is not used in the north due to the low temperature in winter; If the medium is water, drain the water to avoid freezing and damaging the heat sink

Shenzhen ZF HYDRAULIC AND PNEUMATIC PARTS CO.,LTD Production of various types of aluminum alloy air cooler; The company relies on the independent aluminum alloy fin heat sink plate production line; Mastering the core technology is the strong guarantee of reliable and stable dongxu wind cooler. Now the company has independently produced and developed 7 series of more than 200 types of cooler products. Hydraulic system oil cooling, engineering vehicle hydraulic system cooling, lubricating oil cooling, transformer oil cooling, water glycol cooling, air cooling, natural gas cooling gear tank cooling and other fields widely used!