Rexroth piston pump A2FO80/61R-PBB05

How to order:

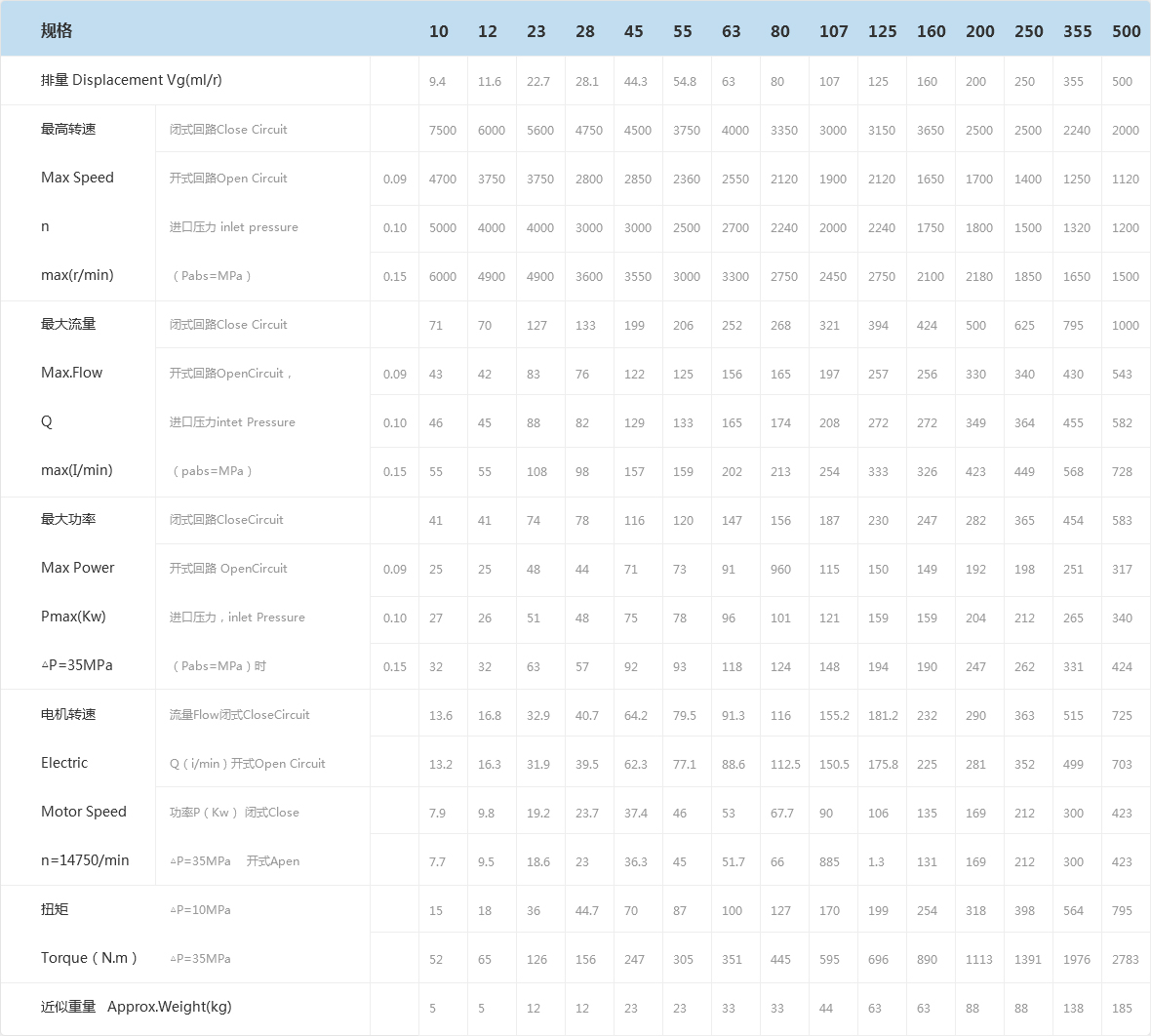

Normal Size:10,12,16, 23, 28, 32, 45, 56, 63,80, 90, 107, 125, 160, 180

Series: 6

Sample: A2FO56/61R-PBB05 (Piston Pump)

A2FM56/61R-PBB05 (Piston Motor)

Pump truck piston pump

| |

|

|

Fixed displacement pumps & motors

• Nominal pressure: Nominal size5: 315 bar

Nominal sizes 10 to 200: 400 bar

Nominal sizes 250 to 1000: 350 bar

• Peak pressure:

Nominal size5: 350 bar

Nominal sizes 10 to 200: 450 bar

Nominal sizes 250 to 1000: 400 bar

• Series 6

• Open circuit

• Robust and short taper roller bearings

• Standard fixed displacement pump for all applications in open circuit

• Service ports SAE or threaded

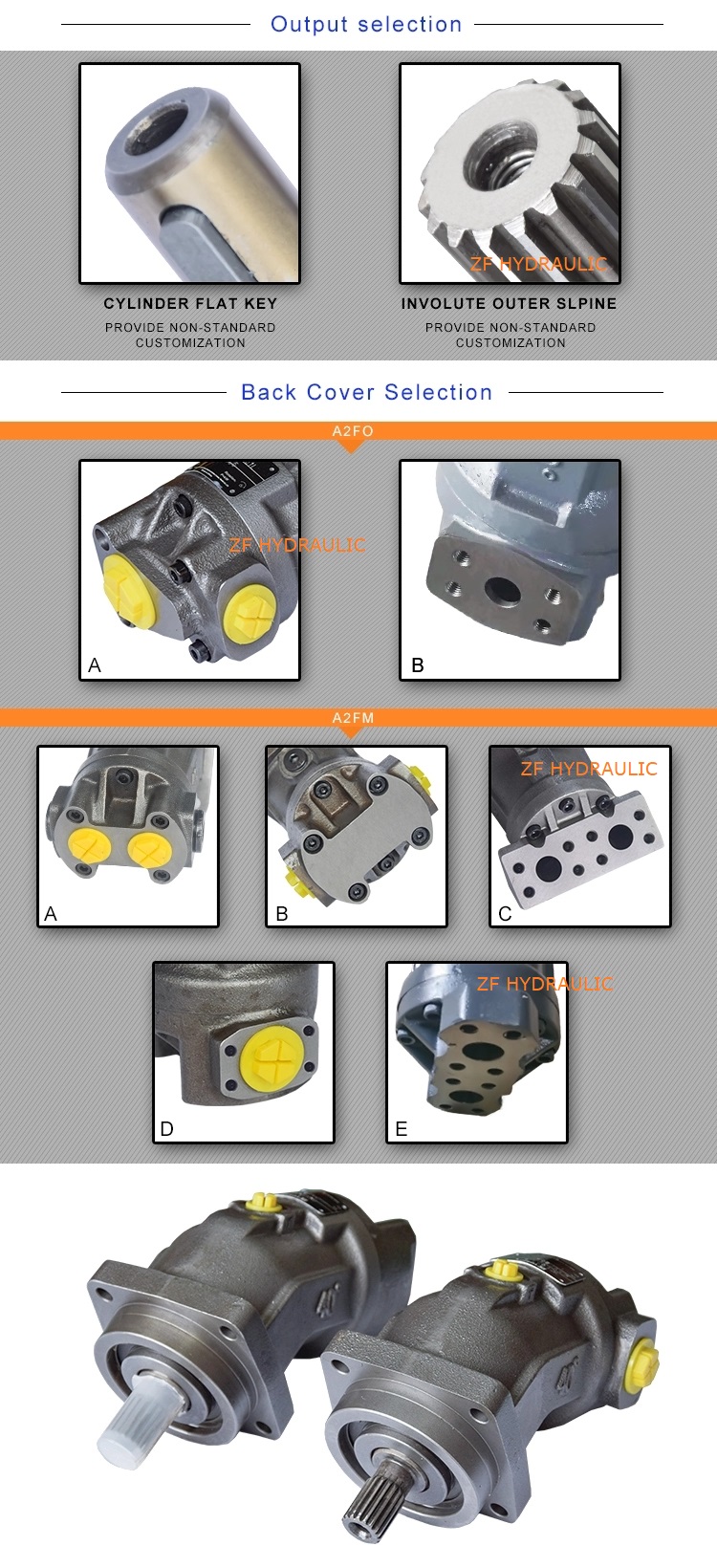

• Cylindrical shaft end with splined shaft or keyed shaft

• Interchangeable with original Rexroth pump and motor of the same model

|

The fixed displacement pump A2F of axial piston, bent axis

design is made suitable for hydrostatic drives in open circuits.

Output flow is proportional to drive speed and displacement. These pumps are suitable for use in mobile or industrial applications. The drive shaft bearings are designed to give the service life expected in these areas of operation.

Careful selection of the displacements offered, permit sizes to be matched to practically every application.

– Favourable power / weight ratio

– Compact and economic design

– Optimum efficiency

– One piece pistons with piston rings

– Patented cylinder block drive system

|

|

Nominal size 5 10 12 16 23 28

|

|

Displacement Vg cm3 4.93 10.3 12 16 22.9 28.1

|

|

Speed 1) nmax min–1 5600 3150 3150 3150 2500 2500

|

|

Flow at nmax qV max L/min 27 32 37 49 56 69

|

|

Power p = 400 bar Pmax kW 9.6 2) 22 25 34 38 47

|

|

Torque p = 400 bar Tmax Nm 24.7 2) 65 76 100 144 178

|

|

Weight (approx.) m kg 2.5 5.4 5.4 5.4 9.5 9.5

|

|

Nominal size 32 45 56 63 80 90

|

|

Displacement Vg cm3 32 45.6 56.1 63 80.4 90

|

|

Speed 1) n min–1 2500 2240 2000 2000 1800 1800

max

|

|

Flow at nmax qV max L/min 78 100 110 123 141 158

|

|

Power p = 400 bar Pmax kW 53 68 75 84 96 108

|

|

Torque p = 400 bar Tmax Nm 203 290 356 400 511 572

|

|

Weight (approx.) m kg 9.5 13.5 18 18 23 23

|

|

Nominal size 107 125 160 180 200

|

|

Displacement Vg cm3 106.7 125 160.4 180 200

|

|

Speed 1) nmax min–1 1600 1600 1450 1450 1550

|

|

Flow at nmax qV max L/min 167 196 228 255 304

|

|

Power p = 400 bar Pmax kW 114 133 155 174 203

|

|

Torque p = 400 bar Tmax Nm 678 795 1020 1145 1272

|

|

Weight (approx.) kg 32 32 45 45 66

|

This series piston pumps other models have:

Pump truck A2FO piston pump A2FO10/61R-PBB05,piston pump A2FO12/61R-PBB05,Pile hammer A2FO piston pump A2FO23/61R-PBB05,piston pump A2FO28/61R-PBB05,piston pump A2FO45/61R-PBB05,piston pump A2FO55/61R-PBB05,piston pump A2FO63/61R-PBB05,

A2FO80/61R-PBB05,ship using piston pump A2FO107/61R-PBB05,A2FO125/61R-PBB05,A2FO160/61R-PBB05,Mining machinery A2FO piston pump A2FO200/61R-PBB05,A2FO250/61R-PBB05,hydraulic station A2FO piston pump A2FO355/61R-PBB05,piston pump A2FO500/61R-PBB05

This series piston motors other models have:

Hydraulic pressure A2FM piston motor A2FM10/61R-PBB05,piston motor A2FM12/61R-PBB05,hydraulic station A2F piston motor A2FM23/61R-PBB05,Piston motor A2FM28/61R-PBB05,Ceramic press A2FM series piston motor A2FM45/61R-PBB05,piston motor A2FM55/61R-PBB05,piston motor A2FM63/61R-PBB05,

A2FM80/61R-PBB05,piston motor A2FM107/61R-PBB05,hydraulic fan A2FM piston motor A2FM125/61R-PBB05,piston motor A2FM160/61R-PBB05,A2FM200/61R-PBB05,piston motor A2FM250/61R-PBB05,piston motor A2FM355/61R-PBB05,piston motor A2FM500/61R-PBB05

|

Safety instructions:

1. A2FO piston pump is designed for use in open loop.

2. Project planning, installation and commissioning of axial plunger units must be carried out by qualified personnel.

3. Please read the instruction manual completely before using the axial plunger unit. You can get it from Bosch rexroth if you need it.

4. There is a risk of burns to axial plunger elements during and shortly after operation. Appropriate safety measures (e.g. wearing protective clothing) should be taken.

5. The characteristics of the axial plunger unit may vary with different working conditions (working pressure, oil temperature).

6. Oil outlet of working pipeline:

· oil port and fixed thread are designed according to the maximum specified pressure. The machine or system manufacturer must ensure that the safety factor of the connecting elements and pipelines meets the specified working conditions (pressure, flow, hydraulic oil, temperature).

· oil outlet of working pipeline and functional oil outlet are only used for hydraulic pipeline.

7. The data and instructions included here must be followed.

8. This product shall not be approved as a component conforming to ISO 13849 general mechanical safety concepts.

9. Overflow valves will be installed in the hydraulic system.

10. The following tightening torque is adopted:

Joint:

See manufacturer's instructions for tightening torque of the joints used.

· mounting bolts:

For mounting bolts with ISO metric threads to DIN 13 and ASME B1.1 threads, it is recommended to check the tightening torque of each box according to VDI 2230.

· threaded hole of axial plunger unit:

The maximum allowable tightening torque MG Max is the maximum for threaded holes and must not exceed this value.

· locking screw:

For the metal locking screws provided with the axial plunger unit, the tightening torque MV required by the locking screw shall be used.

After-sales service:

1. The company will provide free maintenance and technical support for all new products purchased by our company with a one-year warranty, if quality problems occur within the warranty period.

2. After the warranty period, the product to be repaired by our company will be extended for half a year.

3. Ensure long-term operation of equipment by purchasing products and related accessories as required by customers;

4. The after-sales service is not limited by time, and can be solved immediately after receiving the phone call at any time. We will listen to the feedback and deal with it for you in time.

The company employs several domestic senior hydraulic technical engineers resident in the company for technical guidance and participate in the research and development design.

Several engineers with more than 10 years of experience provide customers with independent technical guidance and solutions around the clock.

With advanced digital testing instruments, to provide you with accurate and detailed dynamic curve report.

The parts are all original parts, and can be deeply customized various rare parts.

Provide you with economic repair solutions to repair parts can be repaired as far as possible, try to avoid your additional costs.

With multiple maintenance teams and meeting the needs of multiple customers at the same time, the maintenance can be completed on the same day as soon as possible.

Rexroth A2FO series piston pump displacement models: A2FO5 / A2FO10 / A2FO12 / A2FO16 / A2FO23 / A2FO28 / A2FO32 / A2FO45 / A2FO56 / A

Rexroth A2FO series oblique axial piston pump/motor features: 1. 2. Crankshaft design is more suitable for mobile or fixed applications; 3. The flow is proportional to the transmission speed and displacement; 4. Specially designed drive shaft bearing to provide reliable service life for specific application fields; 5. High power; 6. Compact design; 7. Comprehensive and efficient; 8. Wide pressure range;

Rexroth A2FO series piston pump overview:

Specification 5 to 1000 diagonal axial piston pump open loop series 6 standard quantitative pumps for any application SAE flanged or threaded working end bearing long life (specification 250 to 1000)

5 displacement: common pressure of 315bar/peak pressure of 350bar 10-200 displacement: common pressure of 400bar/peak pressure of 450bar 250-1000 displacement: common pressure of 350bar/peak pressure of 400bar.

Rexroth A2FO series piston pump displacement models: A2FO5 / A2FO10 / A2FO12 / A2FO16 / A2FO23 / A2FO28 / A2FO32 / A2FO45 / A2FO56 / A

Rexroth A2FO series oblique axial piston pump/motor features: 1. 2. Crankshaft design is more suitable for mobile or fixed applications; 3. The flow is proportional to the transmission speed and displacement; 4. Specially designed drive shaft bearing to provide reliable service life for specific application fields; 5. High power; 6. Compact design; 7. Comprehensive and efficient; 8. Wide pressure range;

Rexroth A2FO series piston pump overview:

Specification 5 to 1000 diagonal axial piston pump open loop series 6 standard quantitative pumps for any application SAE flanged or threaded working end bearing long life (specification 250 to 1000)

5 displacement: common pressure of 315bar/peak pressure of 350bar 10-200 displacement: common pressure of 400bar/peak pressure of 450bar 250-1000 displacement: common pressure of 350bar/peak pressure of 400bar.

The above information is from ZF hydraulic