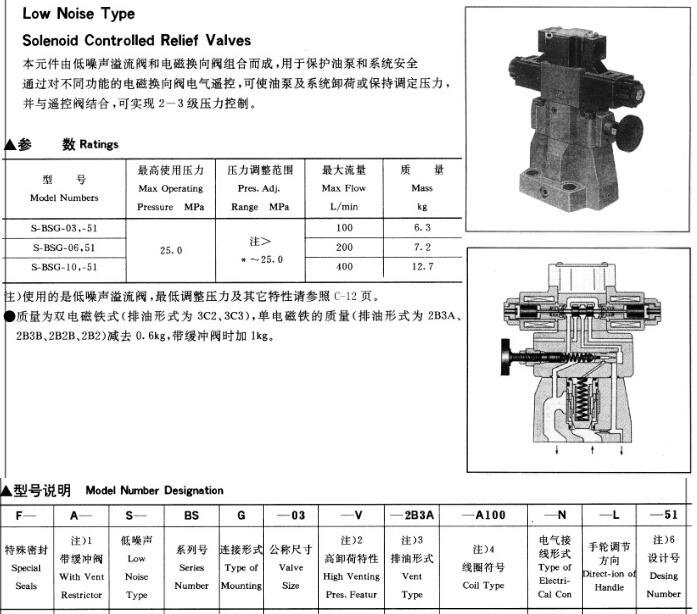

Yuken brand solenoid relief valve S-BSG-06-2B3B-A240-N1-51

How to order:

YUKEN solenoid valve system simple, easy access to the computer, low price. The solenoid valve itself is simple in structure and low in price. What is more remarkable is that the autonomous system is much simpler and much cheaper. As the solenoid valve is switch signal control, it is very convenient to connect with the industrial control computer. In today's computer popularization, the price has dropped dramatically, the advantage of electromagnetic valve is more obvious

Other models:

S-BSG-03

S-BSG-06

S-BSG-10

Matters needing attention

Noise and vibration

The components which are easy to produce noise in hydraulic equipment are generally considered to be pumps and valves. In the valve, overflow valve and electromagnetic directional valve are mainly used. There are many factors that contribute to noise. The noise of overflow valve is the sound of flow rate and mechanical sound. The noise of flow rate is mainly caused by oil vibration, hole and hydraulic impact. Mechanical sound is mainly caused by the impact and friction of components in the valve.

(1) noise caused by uneven pressure

The pilot part of the pilot relief valve is a vulnerable position as shown in figure 3. When overflow occurs under high pressure, the axial opening of the guide valve is very small, only 0.003 ~ 0.006 cm. Small flow area, high flow rate, up to 200 m/s, easy to cause uneven pressure distribution, making the cone valve vibration due to unbalanced radial force. In addition, the cone valve and cone seat processing produced ellipticity, guide valve mouth dirt adhesion and pressure spring deformation, and so on, will also cause the cone valve vibration. Therefore, the guide valve is generally considered to be the source of noise.

Due to the existence of elastic elements (spring) and motion mass (cone valve), which constitutes a condition for oscillating, and the front chamber of the guide valve plays a role of a resonant cavity, the cone valve will easily cause the resonance of the whole valve to emit noise after vibration, which is usually accompanied by violent pressure pulsation.

(2) noise generated by holes

When air is sucked into the oil for various reasons, or when the oil pressure is lower than atmospheric pressure, some air dissolved in the oil will separate out and form bubbles. These bubbles have a large volume in the area of low pressure. When the oil flows to the area of high pressure, they are compressed, and their volume suddenly decreases or bubbles disappear. On the contrary, if the volume is relatively small in the high pressure area, but when it flows to the low pressure area, the volume increases suddenly and the air bubble volume in the oil changes rapidly. The sudden change of air bubble volume will generate noise, and because this process occurs in an instant, it will cause local hydraulic shock and generate vibration. The leading valve port and the main valve port of the pilot type overflow valve, the oil flow rate and pressure change greatly, it is easy to appear cavitation phenomenon, resulting in noise and vibration.

(3) noise generated by hydraulic impact

When unloading the pilot overflow valve, the pressure impact noise will occur due to the sudden drop of pressure in the hydraulic circuit. The higher the working conditions of high pressure and large capacity, the greater the impact noise, which is caused by the hydraulic shock caused by the short unloading time of the overflow valve. When unloading, the sudden change of oil flow rate causes the sudden change of pressure, resulting in the impact of pressure wave. The pressure wave is a small shock wave, which produces very little noise, but when oil is transmitted to the system, if it resonates with any mechanical part, it may increase the vibration and increase the noise. Therefore, when hydraulic impact noise occurs, it is usually accompanied by system vibration.

(4) mechanical noise

The mechanical noise of the pilot overflow valve usually comes from the impact of parts and the friction caused by machining errors.

In the noise of the pilot type overflow valve, sometimes there will be mechanical high-frequency vibration sound, commonly known as self-excited vibration sound. This is the main valve and pilot valve due to high frequency vibration of the sound. Its incidence is related to the configuration, flow rate, pressure, oil temperature (viscosity) and other factors. Generally, the pipe diameter is small, the flow rate is small, the pressure is high, the oil viscosity is low, the self-excited vibration rate is high.