Hydraulic gear pump HGP-3A-F23R-X-2B for sale

Features

HGP-3A Gear Pump function well under high temperature with Viton’s seal. It can also run under high pressure with the oil less bearing design.

Model Definition

|

HGP-3A

|

-F

|

8

|

-R

|

-X

|

-4BJ

|

|

Series

|

Installation Type

|

Displacement

(cc/rev)

|

Input Rotation

|

Input Shaft

|

Front Flange Cover

|

|

Gear Pump 3A Series

|

F: Flange Mounting

L: Foot Mounting

|

6,8,11,13,14,17,19,23,25,28,30

|

R: Clockwise

L: Anti-clockwise

|

X: Straight Keyed

Y: Spline

|

2B: SAE 2-Bolt

4BJ: JIS 4-Bolt

|

Specification

|

Model

|

Displacement

(cc/rev)

|

Pressure

(bar)

|

Speed

(RPM)

|

Port Size

|

Weight

(kg)

|

|

Rated

|

Max.

|

Rate

|

Min.

|

Max.

|

In

|

Out

|

|

HGP-3A-*6*

|

6

|

210

|

250

|

1800

|

700

|

3000

|

PT3/4

|

PT1/2

|

2.32

|

|

HGP-3A-*8*

|

8

|

2.40

|

|

HGP-3A-*11*

|

11

|

600

|

2.53

|

|

HGP-3A-*13*

|

13

|

2.60

|

|

HGP-3A-*14*

|

14.3

|

500

|

2.69

|

|

HGP-3A-*17*

|

16.5

|

2.81

|

|

HGP-3A-*19*

|

19.2

|

2.92

|

|

HGP-3A-*23*

|

23

|

3.11

|

|

HGP-3A-*25*

|

25

|

175

|

210

|

PT1

|

PT3/4

|

3.20

|

|

HGP-3A-*28*

|

28

|

3.29

|

|

HGP-3A-*30*

|

30

|

3.38

|

Product introduction:

Product introduction:

HGP series high pressure gear pump using high strength casting, radial sealing using the addendum sweep chamber, axial seal using floating pressure balance side plate, thus to achieve high efficiency. The pump has small volume, light weight, good performance, reliable work etc. Ontology adopt the aluminum alloy, high precision molding design, low noise, long service life. Especially suitable for petroleum, chemical industry, grain and oil, building materials, daily chemical, construction, electricity and asphalt mixing station departments and industry fuel injection occasion. Also more suitable for work pressure stable, long-term continuous working circumstance, such as: strong lubrication system, etc. Lifting the transport machinery, construction machinery, petroleum machinery, agricultural machinery, and other mechanical equipment. Could with low pressure mass flow vane pump to be high and low pump combination, rational utilization of main energy, cost saving.

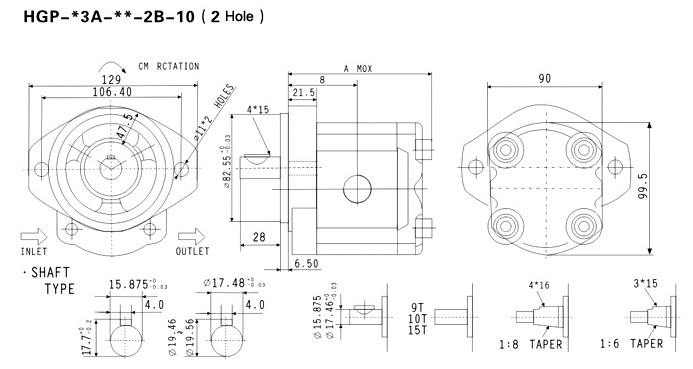

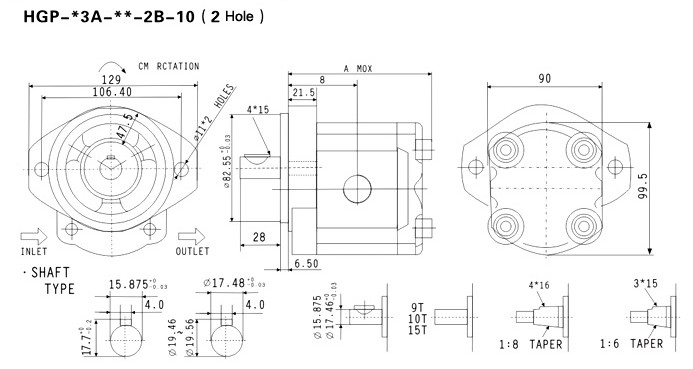

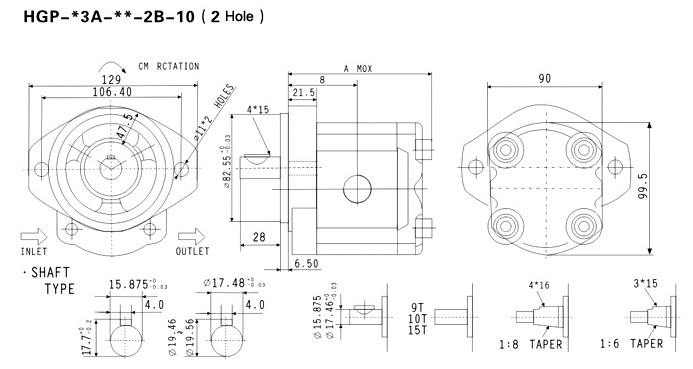

Outside size:

Hydraulic gear pump, hydraulic gear pump action, hgp-2af6r/hydraulic gear pump, crane hydraulic gear pump principle, hgp-2af3r

Hydraulic gear pump, model of hydraulic gear pump, hgp-3af11r/hydraulic gear pump, tractor hydraulic gear pump, hgp-3a-f14r

Hydraulic gear pump, hydraulic double

gear pump, hgp-3af13r/hydraulic gear pump, Volkswagen hydraulic gear pump, hgp-3a-f6r

Hydraulic gear pump, hefei changyuan hydraulic gear pump, hgp-1af2r/hydraulic gear pump, tractor hydraulic gear pump, hgp-3a-f14r

Hydraulic gear pump, hydraulic gear pump factory, hgp-2af12r/hydraulic gear pump, hydraulic gear pump sample hydraulic system, hgp-3a-f23r

Hydraulic gear pump, hydraulic gear pump model r983, hgp-3af30r/hydraulic gear pump, hydraulic gear pump cylinder, hgp-3a-f13r

Hydraulic gear pump, hydraulic gear, gpy-9r/hydraulic gear pump, guangzhou hydraulic gear pump, gpy-2r

Hydraulic gear pump, hydraulic gear pump principle, hgp-2af9r/hydraulic gear pump, tractor hydraulic gear pump type, hgp-3a-f14r

Hydraulic gear pump, hydraulic gear, gpy-9r/hydraulic gear pump, tractor hydraulic gear pump, hgp-3a-f14r

Hydraulic gear pump, 350 mixer hydraulic gear pump, hgp-2af4r/hydraulic gear pump, hydraulic gear, gpy-9r

What is the working principle of gear pump?

Gear pump working principle

The concept of gear pump is very simple, that is, its most basic form is the same size of two gears in a tight fit of the housing meshing rotation, the housing of the internal similar to the "8" shape, two gear installed in the inside, the outside diameter of the gear and on both sides and the housing with a tight fit. The material from the extruder enters the middle of the two gears at the suction inlet and fills the space. With the rotation of the teeth, it moves along the shell and finally is discharged when the two teeth are engaged.

In technical terms, the gear pump is also called positive displacement device, that is, like a cylinder piston, when one tooth into another tooth of the fluid space, the liquid is mechanically squeezed out. Since the liquid is incompressible, the liquid and the tooth cannot occupy the same space at the same time, so the liquid is excluded. As the teeth of the continuous mesh, this phenomenon is continuous in the occurrence, so also in the pump outlet to provide a continuous discharge, pump every turn, the amount of discharge is the same. With the continuous rotation of the drive shaft, the pump also uninterrupted discharge of fluid. Pump flow is directly related to the speed of the pump.

In fact, there is a very small amount of fluid loss in the pump, which makes the efficiency of the pump can not reach 100%, because these fluids are used to lubricate the bearing and gear on both sides, and the pump body is never without clearance with, so can not make the fluid 100% from the outlet discharge, so a small amount of fluid loss is inevitable. However, the pump can still run well, for most extruded materials, still can achieve 93% ~ 98% efficiency.

For viscosity or density in the process of fluid change, the pump will not be much affected. If there is a damper, such as a strainer or a restrictor on the discharge side, the pump pushes fluid through them. If the dampers change during operation, that is, if the strainer becomes dirty, clogged, or the back pressure of the limiter increases, the pump will maintain a constant flow until it reaches the mechanical limit of the weakest part of the device (usually with a torque limiter).

There is actually a limit to the speed of a pump, depending on the process fluid. If the oil is being transferred, the pump can rotate at a high speed, but this limit is greatly reduced when the fluid is a polymer melt with high viscosity.

It is very important to push the high-viscosity fluid into the two-tooth space on the side of the suction inlet. If this space is not filled, the pump cannot discharge the accurate flow rate. Therefore, PV value (pressure flow rate) is another limiting factor and also a process variable. Due to these limitations, gear pump manufacturers will provide a range of products, that is, different specifications and displacement (output per revolution). These pumps will be combined with specific application processes to optimize system capacity and price.

PEP-II pump gear and shaft as a whole, using the whole body quenching process, can obtain a longer service life. The "D" type bearings incorporate a forced lubrication mechanism to allow the polymer to pass through the bearing surface and return to the inlet side of the pump to ensure effective lubrication of the rotating shaft. This property reduces the possibility of polymer retention and degradation. Precision machining of the pump body can make the "D" type bearing and gear shaft with precision, ensure that the gear shaft is not eccentric, to prevent gear wear. The Parkool sealing structure and teflon lip sealing together constitute a water-cooled seal. This seal does not actually touch the surface of the shaft. It is self-sealing by cooling the polymer to a semi-molten state. Rheoseal seals are also available, which are machined with reverse spiral grooves on the internal surface of the shaft seal to reverse pressure the polymer back to the inlet. To facilitate installation, the manufacturer has designed an annular bolted mounting surface to match the flange mounting of other equipment, which makes the manufacture of cylindrical flanges easier.

The pep-ii gear pump is available with optional heating elements that match the pump specifications to ensure rapid heating and heat control. Unlike the way the pump body is heated, the damage to these components is limited to a single plate, not the entire pump.

The gear pump is driven by an independent motor, which can effectively block the pressure pulsation and flow fluctuation upstream. In the gear pump outlet pressure pulsation can be controlled within 1%. Using a gear pump in the extrusion line can improve the flow output speed, reduce the material in the extruder shear and residence time, reduce the extrusion temperature and pressure pulsation to improve productivity and product quality.

Variable vane pump gear pump product display gear pump

Vane pump manufacturer vane pump gear pump

Hydraulic gear pump gear pump manufacturers gear pump model gear pump price

Taiwan xinhong gear pump HGP series gear pump CBB series gear pump

BBB cycloid gear pump GPY series gear pump CBN series gear pump

Pressure switch

Pressure switch