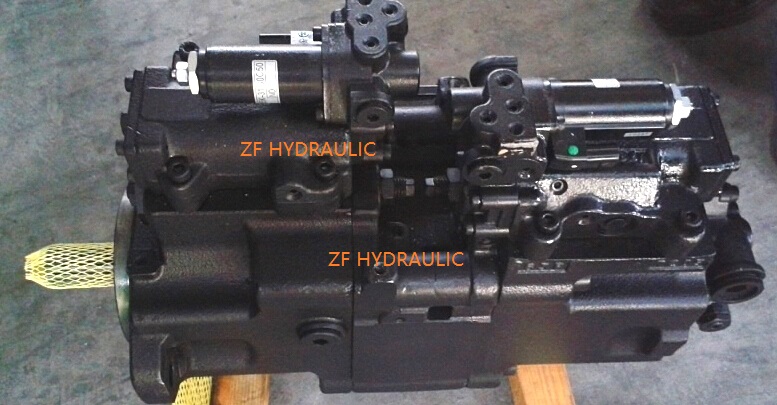

BPA63DTP179R-0513-VC hydraulic piston pump for New Holland E135BSR Excavator

How to order:

|

Pump type:

|

BPA63DTP179R-0513-VC

|

|

Application:

|

New Holland E135BSR, Kobelco SK135 excavator

|

|

Hydraulic control mode:

|

Electronic proportional and Positive flow contol

|

|

Number of solenoid valve:

|

Double

|

|

Feature:

|

Standard pump

|

Excavator hydraulic pump installation notes

(1) ensure that the hydraulic oil is very clean

Hydraulic oil directly into the hydraulic pump, if there are impurities in the hydraulic oil, will wear the plunger, distribution plate and other structures, to the hydraulic pump damage, even make the hydraulic pump scrapped! So the hydraulic oil filter element must be genuine filter element, the greater the density of the general filter mesh, the better the quality of the filter element!

(2) after the installation of the new pump, there is no hydraulic oil, so it should be started strictly and directly. The hydraulic oil should be added to the oil return pipe, and the oil return pipe should not be blocked, otherwise the oil return pressure of the hydraulic pump is too high, which will damage the hydraulic pressure.

(3) pay attention to the discovery of abnormal phenomena at any time

Abnormal sound, vibration or abnormal signals of the monitoring system must have their causes. If you find an abnormal phenomenon, immediately look for the road map, follow the map, and carefully observe whether the abnormal phenomenon is caused by a temporary error. Assess the need for parking treatment. Pressure, load, temperature, time, starting time and stopping time all contain possible causes of abnormal phenomena. At ordinary times that should be discussed item by item analysis.

(4) do not immediately add to the load after the start of the hydraulic pump

After the start of the hydraulic pump must be implemented for a period of time without load idling (about 10 minutes ~30 minutes), especially when the temperature is very low, more must go through the heating process, so that the hydraulic loop circulation normal load, and confirm the operation status.

(5) observe the change of oil temperature

Pay attention to check the highest and lowest oil temperature changes, and find out the relationship between the oil temperature and the external environment temperature, so as to know whether the capacity of the cooler, oil storage tank and the surrounding conditions, the use of conditions to cooperate with each other, the cooling system troubleshooting can also be followed.

(6) pay attention to the noise of the hydraulic pump

New hydraulic pump early wear, easy to be affected by bubbles and dust, high temperature lubrication or poor conditions of use, such as overloading, will cause adverse consequences, making the hydraulic pump out of the normal impact.

(7) check the display value of the meter class

Observe the pressure gauge display value of the hydraulic circuit at any time, the vibration and stability of the pressure on and off lights, etc., in order to find out whether the function of the hydraulic circuit is normal as soon as possible.

(8) pay attention to observe the mechanical action (for the modified pump)

Improper design of hydraulic circuit or component manufacturing is not easy to find in the initial use stage, so special attention should be paid to the action state shown in various conditions of use.

(9) pay attention to the adjustment of each valve

Fully understand the use of pressure control valve, flow control valve and direction control valve, to adjust the scope and limit must pay special attention to, otherwise the adjustment error not only damage machinery, but also pose a threat to safety.

(10) check the state of the filter

The filter in the loop should be taken out and cleaned regularly, and the state of the filter net and the dirt adsorbed on the net should be checked to analyze the quality, quantity and size, so that the pollution degree in the loop can be observed and even the source of pollution can be inferred accordingly.

(11) regularly check the changes of hydraulic oil

Check and analyze hydraulic oil deterioration, discoloration and pollution every one or two months to ensure the normal operation of hydraulic transmission media.

(12) pay attention to the leakage of the piping part

Hydraulic device with good tube, after a period of time in operation can be seen, whether the inspection of oil leakage, whether the pipe is loose.

(13) pay attention to the operation of the new machine within three months

During the operation of the new machine, it is necessary to check the operating conditions, such as the maintenance of the parts, whether the screws are loose, whether the oil temperature rises abnormally, whether the hydraulic oil deteriorates quickly, and whether the operating conditions meet the requirements.